PRODUCT CATEGORIES

At present, the production of complete sets of laying hen has entered a golden period of rapid development. The industrialization of laying hens will be completed by a mechanized, automated and intelligent equipment system. The technical bottleneck in the application of complete sets of equipment is a major problem for most large-scale laying henries problem.

The solution to these problems is not accomplished in a single step. It requires close cooperation between equipment manufacturers and breeding enterprises and the exchange of equipment so that the breeding equipment is more suitable for the production of the modern poultry industry.

6. set egg dung manure equipment

(1) the existing problems:

Egg conveyor belt often fall dust, will be dirty egg surface; egg claw easily broken, inconvenient to replace; egg egg avoid collision, reduce damage; Qing dung with deviation and leakage phenomenon.

(2) solution:

It was pointed out that: egg conveyor to do regular cleaning, some home device with automatic cleaning device, brush with a brush, if you do not have to clean up, but the automatic cleaning can greatly reduce the labor intensity of the feeder. In the installation and design, the egg claw should consider not only the convenience of replacement, but also the best quality materials. In order to avoid the collision of eggs, the speed of the conveyor belt should be set reasonably, and the buffer device can also be considered.

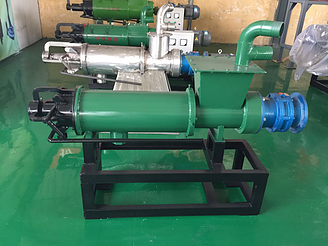

7. chicken manure, dead chicken handling facilities

(1) the existing problems:

Many farms use manure dung to clear manure, not only for a long time (about 45 minutes each), but also for the manure to twist back and forth. Chicken manure becomes very thin and not easy to handle. There is no uniform handling of dead chickens, lack of phase Supporting processing facilities.

(2) solution:

At present, some chicken farms make full use of the chicken coop's own heat to dry the chicken manure to a certain extent and then clean up, so that no environmental problems will be caused. Some companies consider investing in biogas power generation equipment.

Some people pointed out that: biogas power generation is not suitable for all enterprises, we should do what we can, without project funding, or not easy to invest because of the high cost of biogas power generation into the State Grid, the price control by the state, from the economic point of view and Not worthwhile. In some countries such as Japan, chicken manure is usually treated with natural compost fermentation, this method is simple and feasible.

It has been pointed out that at present most chickens handling dead chickens are incinerated or buried. If the measures are not put in place, they will cause environmental pollution. In some places, attempts are being made to make pellets of dead chickens as fish feed, pig feed These are all worth exploring.

8. find the fitting point of the production and use of the equipment

(1) equipment production enterprises should face the problem directly

Some people think: now an embarrassing phenomenon is chicken do not understand the equipment manufacturing, equipment manufacturing will not understand the chicken, domestic equipment companies to imitate the main door, causing serious phenomenon; the lack of horizontal cooperation and vertical exchanges between enterprises, it should learn from the young chicken enterprises; enterprises generally focus on sales, light development, the phenomenon of light service; most of the products are "three noes" (no label, no instruction, no product certificate) products; product use and maintenance manual is not perfect, most companies do not have the equipment components; the low level of standardization, technical parameter is not perfect; the purchase and sale contract without a unified version of some of the terms of overlord part; factory installed personnel 8 hours work system is not reasonable, the enthusiasm of the installation personnel is not enough, not strong sense of responsibility.

(2) the planning and design of chicken house should be scientific and reasonable

It was pointed out that: in the actual operation, sheds architectural drawings to make equipment factory, and ensure equipment; sheds water and electricity, monitoring circuit to do the design, pre buried in the ground and the wall can not be exposed in the henhouse henhouse before and after leaving; both ends on both sides and the middle gate, do not leave the ditch; in the equipment investment to one step, not to seek refinement, planning and design, step by step; equipment selection should consider the actual needs of production, the height of the cages should meet the demand of 120 day old chicken; equipment automation automation, because the future labor costs will be higher; water and electricity warm, wearing parts to have a backup, once insufficient to replenish, or will cause great loss; staff recruitment, training to be synchronized with the field construction.

(3) the link between production and use of equipment needs to be connected

In the view, now young chicken breeding process can do kettle, tray, bottom three no, it can greatly reduce the labor intensity, so laying hens become more simple, but also can achieve a 36 hours after feeding trough without feeding, feed and not moldy, these methods of farming enterprises to find out in the application in the process of enterprise equipment is unexpected.

Therefore, designers of equipment enterprises need to go deep into the chicken farm, listen to the advice of the staff, consider the problem from the perspective of the breeder, design and use the equipment and make more use of the nature of the chicken. In addition, many poultry farms are from different manufacturers. How to ensure the supporting installation, seamless docking and normal operation of these facilities is also a practical problem to solve.

Pre:How much you know about Farm chicken equipment

Next: Christmas Party

(* Guarantee your email safe absolutely)